Green Products and Innovation

Sustainable Production

USI actively introduces smart manufacturing through the automated lights-out factory project to streamline production quality and efficiency, meet customer demand, and continue optimization of design, production, and energy efficiency through the Continuous Improvement Program.

Smart Manufacturing

USI's Smart Manufacturing Program has adopted the concept of Industrial Internet of Things (IIoT) and plans the development of the Industry 4.0 Smart Manufacturing Program in line with the electronic manufacturing industry, and this is called the 5-Star Industry 4.0 Smart Manufacturing. In 2023, we successfully introduced 62 automated manufacturing projects, saving a total of CNY 300 million in labor costs, with an average of 2.62-Star Facilities.

The Company plans to upgrade all facilities with implementation of Industry 4.0 to 2-Star or 3-Star factories in 2028, such that the average class of facilities will reach 4.28-Star. USI aims to implement Lights-Out Factory in all facilities worldwide, at least building one fully automated smart manufacturing production in each facility.

Lights-Out Factory Roadmap

Continuous Improvement Program (CIP)

Continuous Improvement Program (CIP) proposes improvement plans for the productivity, process, quality, efficiency, equipment, software, hardware, energy conservation and CO2 emission reduction, automation, safety, digital innovation, and have cost saving benefits. Its purposes are as follows:

- Build a platform to realize ideas and approve employees' endeavors and awards

- Encourage employees devoting to continuous improvement

- Enhance teamwork and enterprise competitiveness

After the 2023 annual performance examined and approved by Corporate Review Committee (CRC), the actual tangible cost saving was CNY 108.7 million. The saving cost accounted for 0.27% of revenue and a total of CNY 1.03 million has been reward employees for their commitment to continuous improvement.

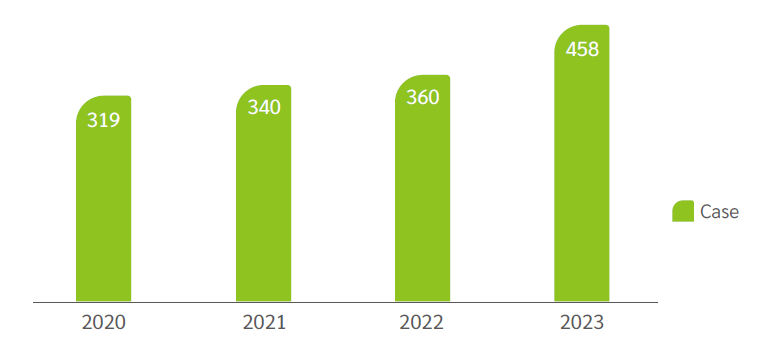

Proposed New Cases of CIP

In response to the issue of climate change, we have included Energy Saving and Carbon Reduction in the rating system and the type of key project to promote relevant green proposals. In 2023, there were 4 energy-saving and carbon reduction projects receiving awards, an increase of 2 projects from last year. The total carbon reduction amount increased by 1,561 metric tonnes.

| Facility | Ranking | Project Name | Key Project Benefit |

|---|---|---|---|

| Kunshan | Gold | Near Zero-Carbon and Energy Saving Technology | Through the improvement of the facility system techniques and replacement of equipment with high energy efficiency, energy saving, and emission reduction is achieved along with the reduction of energy consumption expense. This project received the honors of first group of Near Zero-Carbon Factory in Suzhou City and provisional Green Factory award, saving 130,000 kWh of electricity annually and reducing carbon emissions by 103 metric tonnes, with cumulative annual savings of CNY 1.30 million. |

| Zhangjiang | Silver | Expansion and Energy Saving Project of Nitrogen Station | The original nitrogen production technique is improved (use of the technique of liquid nitrogen refilling and cryogenic air separation to extract nitrogen, such that the process requires shorter purification time, lower energy consumption and higher extraction rate), in order to reduce the nitrogen production cost. In addition, according to the nitrogen demand, excessive dry air is used for the Clean Dry Air (CDA) system, in order to flexibly adjust gas resource, saving 3,000,960 kWh of electricity annually and reducing carbon emissions by 2,428 metric tonnes, with cumulative annual savings of CNY 1.79 million. |

| Jinqiao | Bronze | Energy Saving Improvement of Process Cooling Water (PCW) System | Two independent PCW systems are integrated into one system. With the synergy effect of water supply pressure and the floor gravity water pressure, water supply pressure can be reduced effectively, and the pressure relief of the drain valve is reduced, saving 501,600 kWh of electricity annually and reducing carbon emissions by 211 metric tonnes, with cumulative annual savings of CNY 0.41 million. |

| Zhangjiang | Bronze | Water Clean Machine Energy and Water Saving Program | The Programmable Logic Controller (PLC) program of the water clean machine is set in such a way that if no product is received, the workstation and air cooler are stopped from running, in order to save energy and water consumptions of the water clean machine, saving 318,567 kWh of electricity annually, saving 8,768 metric tonnes of water annually and reducing carbon emissions by 135 metric tonnes, with cumulative annual savings of CNY 0.20 million. |